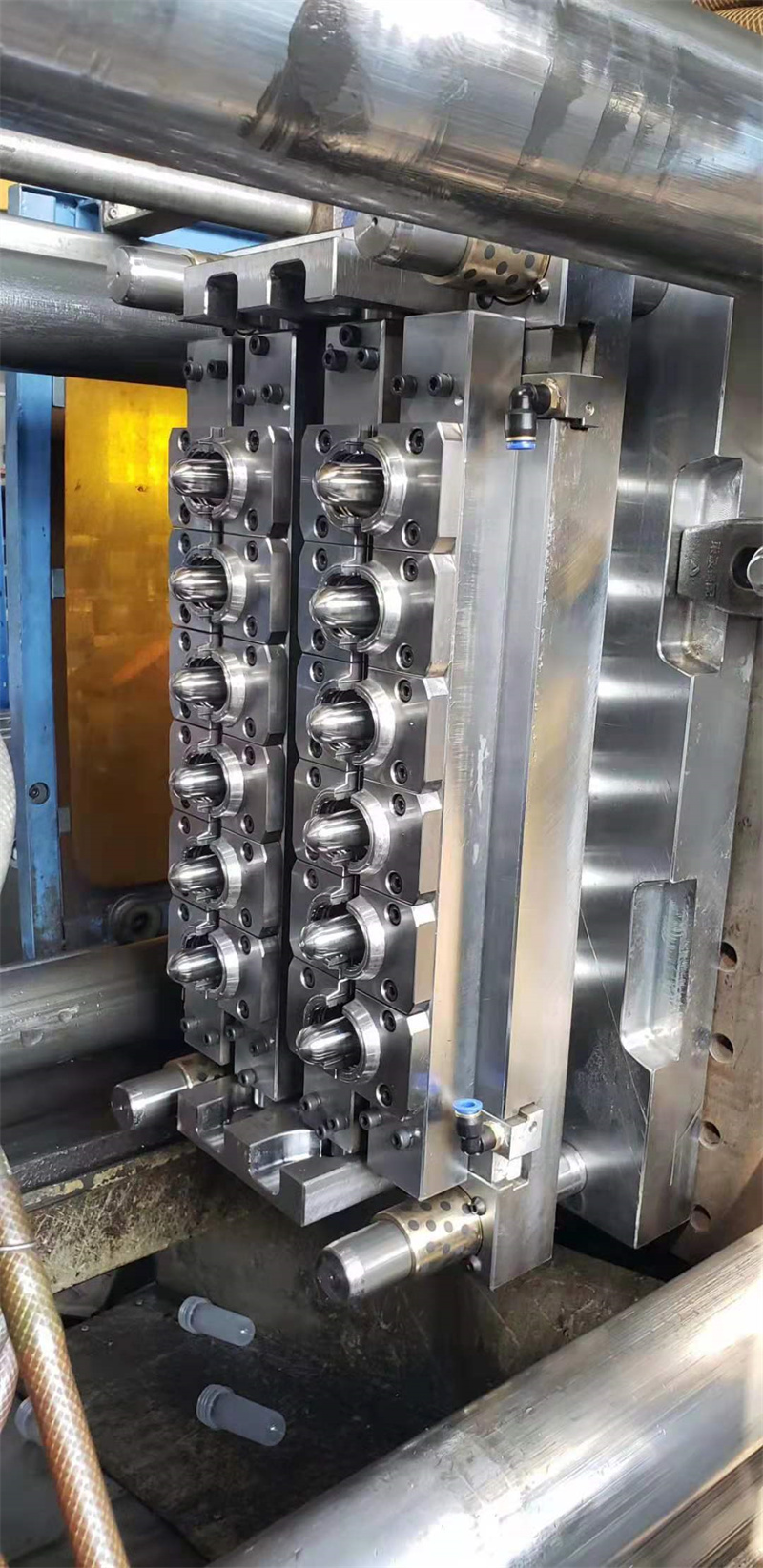

12 Cavity PET Preform Mold

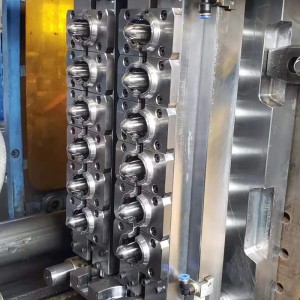

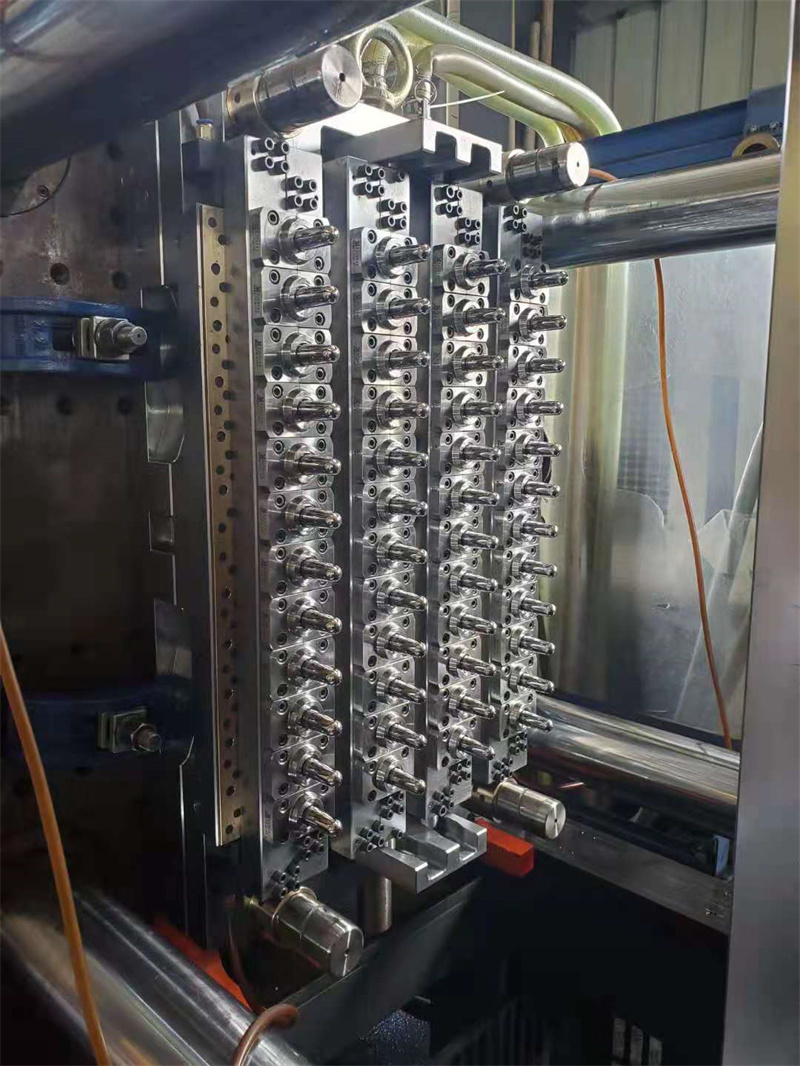

48-cavity pin valve PET preform hlobo

1. Semathi se chesang se amohela mokhoa oa ho laola PID, o khetholloang ka ho lokisoa ka mokhoa o itekanetseng le mesebetsi ea ts'ireletso e ikemetseng, e ka lelefatsang bophelo ba tšebeletso ea mochine oa ho futhumatsa motlakase;

-Mocheso o laoloa ka hare ho 1 ° C ho etsa bonnete ba hore lihlahisoa tse tala ha li chesoe ho semathi se chesang, 'me sekhahla sa sehlahisoa se felile se ka fihla ho feta 99%;

-Moqapi o mocha oa nozzle o etsa hore hlobo e be bonolo ho e boloka, karolo ea thimble ea nozzle, karolo ea ho futhumatsa, karolo ea ho kenya mocheso, le thermocouple e ka nkeloa sebaka habonolo ntle le ho qhaqholla hlobo, e leng molemo ho fokotsa nako le ho boloka litšenyehelo tsa tlhokomelo. .

2. Sistimi e phodileng

-The spiral cavity pholileng mocha oa metsi o etsa hore phello e pholileng e be matla.

-Sekanale sa metsi a pholileng boema-kepeng ba likhoele le selaete se ntlafatsa phello ea ho pholisa.

-Letlapa la kabo ea bohareng le etselitsoeng hantle, metsi a pholileng a ka kenngoa ka har'a sekoti se seng le se seng, 'me li-preforms tsohle li ka pholile ka mokhoa o ts'oanang le ka potlako.

3. Semathi se chesang

- Semathi se chesang se nang le ts'ebetso e ntle ea ho leka-lekana se tiisa hore phallo le khatello ea PET e qhibiliha ka har'a likoti tsohle li lekana.

-PET melt channeling e fokotsa tahlehelo ea shear le IV mme e lumella PET hore e qhibilihe hore e phalle ka mokhoa o lekanang ho likoti tsohle.

- Kabo e nepahetseng ea mocheso e boloka litaba tsa acetaldehyde (AA) ka har'a likoti tsohle li tsitsitse.thepa

Lintho tse Tloaelehileng 632: E betere ho feta FS136 e nang le nickel e phahameng le chromium content.

Ho thatafala, ho hanyetsa mafome, le phello e tšoeu ho hlakile hore li ntlafetse.

Setsi sa hlobo se entsoe ka HRC 38 ~ 40 tšepe e sa hloekang kapa P20 (e tiileng pele).

2. Moralo oa stack oa mofuta oa SelfLock

Pele o koala hlobo, seam se arolang se notletsoe sebakeng ka selikalikoe sa ho notlela ho fokotsa ho roala ha mohala ka lehlakoreng le bohareng, ka hona ho lelefatsa bophelo bo se nang burr ba mohala oa karohano.

Selelekela sa Tlhahiso ea Mold

| Mofuta | Bophahamo(mm) | Bophara(mm) | Botenya(mm) | Boima(kg) |

| 6 Cavity | 650 | 270 | 490 | 600 |

| 8 Cavity | 480 | 360 | 490 | 595 |

| 12 Cavity | 610 | 360 | 490 | 755 |

| 16 Mokoti | 740 | 360 | 510 | 960 |

| 24 Cavity | 790 | 500 | 510 | 1415 |

| 32 Cavity | 800 | 580 | 510 | 1600 |

| 48 Cavity | 1120 | 600 | 560 | 2640 |

| 64 Mokoti | 1380 | 600 | 610 | 3545 |

| 72 Cavity | 1170 | 800 | 610 | 4010 |

| 96 Mokoti | 1230 | 960 | 610 | 5050 |

Lintlha tse ka holimo li thehiloe ho preform ea 16g e nang le molala oa PCO.

48-cavity e tiisitsoeng ke PET preform hlobo

1. Likarolo tsa hlobo:

1. Re sebetsa ka ho khetheha ho hlahiseng hlobo ea li-valve tsa nale, tse sa hlokeng ho itšeha ka letsoho.

2. Tšebeliso ea tsamaiso e tsoetseng pele ea semathi se chesang e tiisa hore boleng ba AA ba sehlahisoa bo boemong bo tlaase.

3. Moralo o utloahalang oa mocha oa metsi a pholileng o matlafatsa phello ea pholileng ea hlobo 'me o khutsufatsa ka katleho potoloho ea ho bopa ente.

2. Khetho ea lintho tse bonahalang:

1. Likarolo tse ka sehloohong tsa hlobo li entsoe ka thepa ea S136 e tsoang linaheng tse ling (Sweden-Sabak).

2. Thepa ea motheo ea hlobo e amohela thepa ea P20 e tsoang linaheng tse ling le phekolo ea electroplating, e ntlafatsang ho hanyetsa ha hlobo ea hlobo le ho lelefatsa bophelo ba tšebeletso ea hlobo.

3. Phekolo ea mocheso ea likarolo e sebetsoa ka sebōpi sa vacuum se tsoang Jeremane, 'me ho thatafala ha likarolo ho tiisetsoa ho ba HRC45 ° -48 °.

4. Lisebelisoa tse tsoetseng pele tsa ho sebetsa:

Khampani e hlahisitse lisebelisoa tse ngata tsa mochine tse tsoang United States le Japane, tse kang litsi tsa machining, CNC lathes, EDM, joalo-joalo, ho etsa bonnete ba ho nepahala ha machining ea likarolo le ho etsa hore likarolo li be le phetoho e ntle., phoso ea boima e ka tlase ho 0.3g, hlobo ea 2-5 e ka hlahisoa ka motsotso o le mong, 'me bophelo ba tšebeletso bo ka fihla makhetlo a limilione tse 2 hlobo.

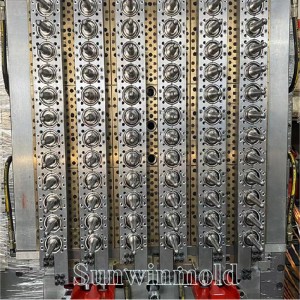

24 cavity preform hlobo

Sebopeho sa hlobo se secha sa preform se entsoeng ka boithaopo se entsoeng lipatlisiso le ho ntlafatsoa se ka felisa ka ho feletseng boholo ba bofokoli ba liforomo tse fetileng, 'me se ka finyella concentricity e phahameng ea ho nepahala le bophelo bo bolelele ba hlobo,' me se ka phethahatsa litekanyetso tsa likarolo tse sa tšoaneng tsa hlobo le tlhahiso ea bongata.Mefuta ea rona e netefatsa hore phapang ea botenya ba lerako la tube e se nang letho e ka tlase ho 0.05mm, mme phoso ea boima e ka tlase ho 0.3g.2-5 hlobo e ka hlahisoa ka motsotso o le mong, 'me bophelo ba tšebeletso bo ka fihla makhetlo a limilione tse 2.Hlobo e na le likoti tse 96.

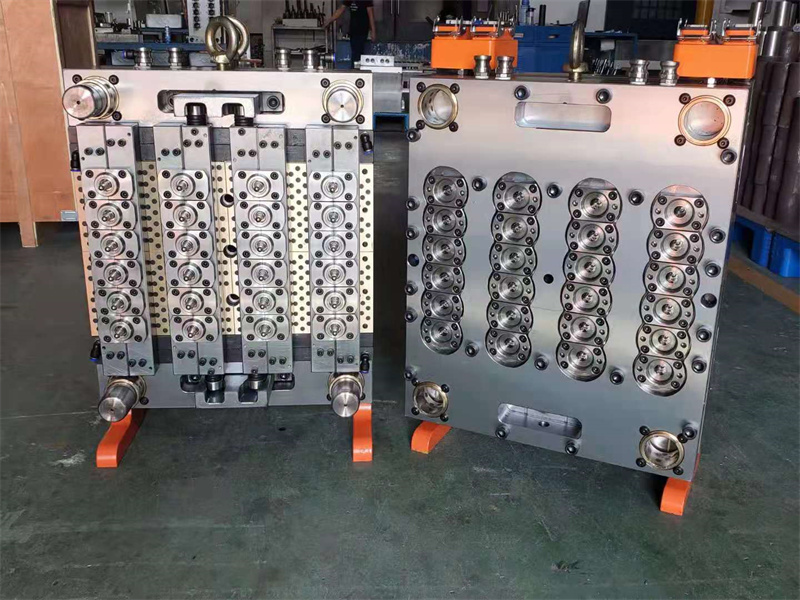

48-cavity e tiisitsoeng ke PET preform hlobo

1. Boiphihlelo ba profeshenale le botekgeniki ho likoti tsa hlobo tsa preform ho tloha ho 1 ho isa ho 96 cavities.

2. Sebopeho sa preform se sebelisa software ea CAD ho theha sebopeho sa preform ho latela botlolo ho netefatsa boleng ba ho bopa botlolo.

3. Thepa ea ho bula khoele ea hlobo ea preform e entsoe ka tšepe ea nitrided e tsoang linaheng tse ling, e entsoeng ho ea ka litekanyetso tsa machaba, e nang le boima bo phahameng, khoele e 'ngoe le e' ngoe e na le moea, 'me e na le bophelo bo bolelele ba tšebeletso ntle le deformation.

4. Mokotla oa hlobo oa preform le cavity li entsoe ka tšepe e sa tsitsang, e tšoarellang nako e telele.

5. Mofuta oa preform o amohela moralo o tsoetseng pele oa semathi se chesang, e le hore sekoti se seng le se seng se ka khona ho laola mocheso, ho futhumala, 'me mocheso o lekana.

6. Sekha-mahala heke preform hlobo, ho pholosa mosebetsi le thepa e tala.

7. Mocheso oa nozzle ea semathi se chesang o laoloa ka thoko.(Ho rarolla bothata ba ho soeufala le ho taka mohala ka tlase nakong ea ts'ebetso ea tlhahiso).

8. Needle-valve self-locking hlobo preform: e 'ngoe le e 'ngoe ea mantlha, sekoti, ho ikemela ka makhetlo a mabeli, ho ikemela ka mokhoa o feto-fetohang, ho fokotsa eccentricity, ho netefatsa concentricity ea sehlahisoa, ho nepahala ho phahameng.Hlobo e na le nako e telele ea tšebeletso.

9. Ts'ehetso ea sampole le ts'ebetso ea ho taka, fana ka nts'etsopele ea sehlahisoa se secha, ts'ebeletso e le 'ngoe bakeng sa ts'ebetso ea ho bopa ente!

12 cavity PET preform hlobo

1. Ho sebelisoa sekoti sa tšepe sa S136 se tsoang linaheng tse ling, konokono, le molala oa khoele li sebelisoa, 'me boima ba phekolo ea mocheso bo ka fihla HRC 48-50;liforomo tsohle li phekoloa ka mocheso ka boima ba HRC 30-35.

2. Theknoloji e tsoetseng pele ea ho theha hlobo: Mokhabo o mong le o mong o ikemela ka boithaopo, o sebelisa SYATEM ea Japane e phahameng ka ho fetisisa.Ho etsa bonnete ba hore palo e tlase ea 'mele le ho nepahala ha sehlahisoa.Lefu le leng le le leng le na le li-spare tse kenyang likarolo tse tšoarellang tse feto-fetohang.E le ho ntlafatsa le ho finyella katleho e phahameng ea tlhahiso, re lula re theha tsamaiso e ntle ka ho fetisisa ea ho pholile, 'me e ka bapisa mochine o pholileng bakeng sa hlobo e' ngoe le e 'ngoe.

3. Sebapali se chesang se tsoetseng pele le se nepahetseng sa li-valve le molaoli oa mocheso li netefatsa ho tšepahala ha tlhahiso le phetisetso ea khanya e phahameng le khanya ea sehlahisoa.

4. Mofuta o thellang o entsoe ka koporo, 'mele oa botlolo o kopana le tekanyo ea tšireletso ea lijo,' me bophelo ba hlobo bo tiisitsoe ho feta makhetlo a limilione tse 3. 1.Litšobotsi tsa hlobo:

1. Re sebetsa ka ho khetheha ho hlahiseng hlobo ea li-valve tsa nale, tse sa hlokeng ho itšeha ka letsoho.

2. Tšebeliso ea tsamaiso e tsoetseng pele ea semathi se chesang e tiisa hore boleng ba AA ba sehlahisoa bo boemong bo tlaase.

3. Moralo o utloahalang oa mocha oa metsi a pholileng o matlafatsa phello ea pholileng ea hlobo 'me o khutsufatsa ka katleho potoloho ea ho bopa ente.